Betting on the next battery winner – Max Range or Max Power?

It’s time to spark a conversation about the next frontier in battery technology – power-dense, ultrafast charging batteries.

In a world where time is money and downtime is the arch-nemesis of progress, we find ourselves at the cusp of a technological metamorphosis. The battery industry, with its insatiable appetite for innovation, is hurtling towards a future where energy-dense batteries are the norm and maximum range has become the pinnacle for innovation. But who exactly is demanding maximum range? And at what cost?

Are EV drivers demanding increasingly more range?

The average accessible range for a light-duty battery electric vehicle today is 68.8 kWh, while range-leaders like the Fisker Ocean, Volvo EX90 and the Polestar 3 supply their customers with over 300 miles of range in their 100kWh-plus battery packs 1.

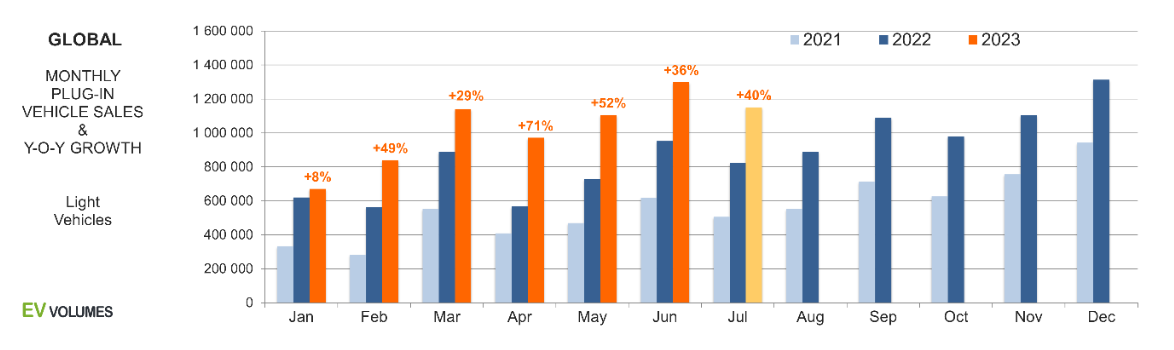

With the year-on-year global growth in battery electric vehicles (BEVs) and plug-in hybrid electric vehicles (PHEVs) and expected sales in 2023 of 14 million EVs globally2, it would appear there is healthy, continuous demand for EVs at the current range offerings.

In fact, the top battery producers in the world (household names like CATL, LG Energy Solutions, BYD, Panasonic, SK One and Samsung), experienced an impressive 65% growth in demand from the automotive sector in 2022, from 330 GWh to 550 GWh3. It’s clear that while battery packs for EVs continue to push 100kWhs, and overall EV sales increase, the demand and supply for high energy-density battery cells will continue to be strong.

Source: EV-Volumes

What’s the right recipe for power and range?

It depends. It’s clear that passenger EVs are leaning towards large, long-range packs for now, but it’s crucial to acknowledge that they are not ideally equipped for ultra-fast charging now. This isn’t a criticism but rather a realistic assessment of the current state of rapid charging infrastructure and the power acceptance of traditional lithium-ion batteries on the road today.

On a 150 kW rapid charger commonly found in the U.S., an EV such as a Tesla Model S with an 85 kWh battery would be able to replenish about 200 miles in 30 minutes. For drivers topping up over a road trip lunch or city-dwellers who charge up once a week, this might feel like a perfectly acceptable charging service.

However, for more rushed industrial operations, where time is money, getting this charge time below 10 minutes, at the trade-off of slightly less range would be key. To get there, you need a charging source with high enough power to fill the battery in minutes, and then a high-power battery (and more importantly cell chemistry) that’s able to accept that charge.

Enter the Nyobolt EV… here we’ve taken lengths to develop an extreme counter example to the industry norm: A relatively small, power-packed 35 kWh battery that can fully charge in 6-minutes on a 350 kW DC charger, and can deliver 155 miles (or 250 kms) of range. That’s more than adequate for a typical daily driver and more convenient to recharge when time is tight.

Now imagine this pack could be scaled down to power professional-grade construction tools or autonomous mobile warehouse robots, or scaled up to power heavy commercial vehicles that need to be running a full workday. In this world, battery systems capable of delivering high-power, ultrafast recharge, strong regen, and a long cycle life will change the game for certain commercial industries. A game where maximum range at the expense of crippling charge times is not the answer.

Are we ready for the “ultra-fast” charging movement?

Firstly, battery technology, while advancing rapidly, still has limitations. The incumbent lithium-ion batteries commonly used in EVs on the market today have specific constraints related to heat dissipation and chemical reactions. Rapid charging generates more heat, which can be detrimental to the long-term health and efficiency of the battery.

Moreover, the existing charging infrastructure is not optimized for ultrafast charging. Most public rapid charge networks have been built to deliver between 50 kW and 150 kW of direct current. While we’re seeing an increase in power output up to 400 kW in Europe or even up to 600 kW in China, at the same time, the EV needs to be able to accept the higher power source which is not always the case. If a vehicle has been designed to accept a maximum of 100 kW of power, then charging at a 400 kW charger will only yield a maximum power of 100 kW.

Nyobolt is working with customers in high-uptime, high power sectors to design their charging infrastructure, routes and charging cycles to optimize the number of machines and battery pack sizes in operation, while raising the efficiency of the fleet.

And for locations where high-voltage DC charging infrastructure is just not available, the Nyobolt mobile supercharger Bolt-ee can step in to help. Read more about it here.

So, who’s the winner?

We all hate a tie but the answer is that both high-energy and high-power batteries have a place in the electrification movement, meeting the needs of different segments.

In long-range applications where energy density is key, some EV categories, maritime and aerospace applications are likely to continue to demand larger batteries packed with range in the near term.

Other industries which favor high power-dense, fast charge batteries will benefit from condensed, more efficient packs. At Nyobolt, we’ve seen interest from the likes of industry leaders in Formula E and other high-performance EV makers, material handling warehouse robots, professional tools and appliances, mine-haul trucks, and commercial goods vehicles such as last-mile delivery vans and two-wheelers.

In these industries where time is money, high-uptime, powerful machines running over tens of thousands of lifecycles will likely set a new benchmark for the definition of “fast-charging” and we plan to be on the right side of history, supplying that demand.

1 https://ev-database.org/uk/cheatsheet/useable-battery-capacity-electric-car

2 https://www.iea.org/reports/global-ev-outlook-2023/trends-in-electric-light-duty-vehicles

3 https://cleantechnica.com/2023/09/18/top-battery-producers-in-the-world/

4 https://pod-point.com/guides/driver/how-long-to-charge-an-electric-car

Stay Updated with Nyobolt Insights

Subscribe to our free newsletter